Project description

Project summary:

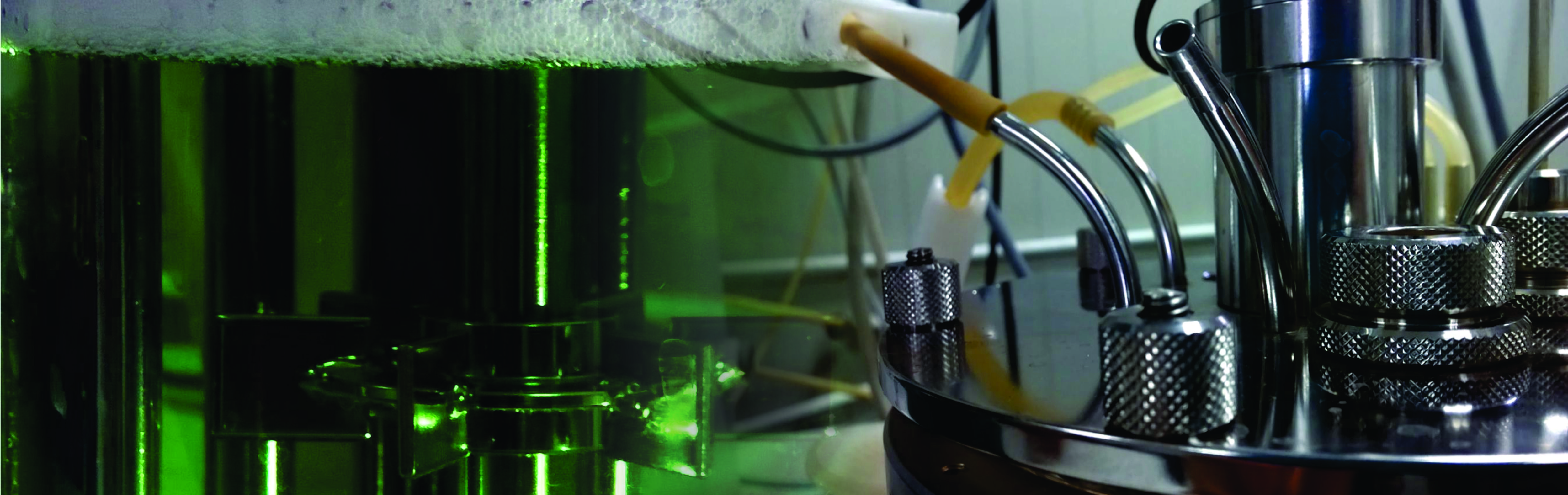

The main objective of BIOCON project is the experimental analysis and the efficiency increasing through automation methods of a complex plant of biorefinery type. The biorefinery plant consists in a coupling of two processes: an anaerobic digestion one and a microalgae photosynthetic growth process in photobioreactors. This plant is used for obtaining biomass from microalgae in order to produce components with added value, bio-mitigation of the CO2 emissions obtained from methane combustion and its use as a substrate for the microalgae photosynthetic growth process. At the same time, the use of the biomass residues as a substrate for the biogas production in the anaerobic phase and the process of methane obtaining in anaerobic fermentation processes are also studied. To achieve the project objectives with the available resources, a biorefinery plant having a structure based on a modern concept of HIL (Hardware in the Loop) has been adopted in the project. This structure means the coupling between an experimental structure (the photobioreactor for the microalgae photosynthetic growth process) with a software structure (the anaerobic digestor). It can be mentioned that the HILS structure used in the project behaves similarly to the experimental plant of biorefinery type.

The scientific contributions consist in automation solutions for a very complex process (with strong nonlinearities, characterized by parametric and model uncertainties and affected by disturbances); mathematical models for the two processes (the anaerobic digestor and photobioreactor), the coupling between a software entity (the anaerobic digestor) and an experimental one (the photobioreactor for the microalgae photosynthetic growth process), a prototype of the biorefinary plant (in a HIL structure) controlled by an advanced system implemented on a process computer, advanced control solutions for the overall biorefinery plant. The main novelty and originality characteristics of the project consist in the systemic approach (modeling and control) of the biorefinery for which few references can be found in the literature. The following main objectives of the project can be mentioned: modeling of the anaerobic digestion, modeling of the microalgae photosynthetic growth process and its identification for the control purposes based on experiments carried out on the pilot plant, synthesis of control algorithms (optimal and fuzzy) for both processes (anaerobic digester and photobioreactor) treated individually as well as coupled, through numerical simulations and implemented on the biorefinery plant designed based on the HIL concept. The project also encourages the photosynthetic growth processes through the usage of low-cost substrates, such as the wastewaters and the CO2 resulted through methane combustion. It must be mentioned that both processes and technologies are approached in the project through a systemic-engineering manner, specific to process automation. The team involved in the project consists in four entities, each of them having a rich experience in conducting scientific research projects: Coord. – „Dunarea de Jos” University of Galati, P1 – University of Craiova, P2 – Polytechnic University of Timisoara and P3 – TeamNet Engineering Company. The team consists in specialists in automation, process informatics, biotechnology, thus fulfilling the interdisciplinary characteristics of the project. The workload is rigorous and well balanced, all the involved institutions having a high level human resources and corresponding logistics, thus promising positive premises in reaching the expected results.